| ISO 9001 | ISO 13485 | CE 1984 | EMC | LVD |

Teknomar Brand Ethylene Oxide Gas Sterilizer Acidic Scrubber

Ethylene oxide is used as sterilant for sterilization of heat and humidity sensitive medical and surgical products. Ethylene Oxide consists of C2H4O molecular formula. It is colorless, flammable and toxic gas in room temperature and pressure. It is a bactericidal, fungicidal, and sporicidal disinfectant effective against most micro-organisms, including viruses.

Main Sterilization Process of Ethylene Oxide Sterilization Device:

- - Pre-Conditioning

- - Sterilization

- - Neutralization

At the Pre-Conditioning phase, the items loaded in under vacuumed chamber are exposed to heat and moisture for maintaining an environment for microorganisms to be alive.

At Sterilization Phase, products are exposed to sufficient Ethylene Oxide (ETO) gas under vacuumed chamber at a certain time to kill microorganism.

The most significant and critical phase is Neutralization, which begins with de-gassing process.

What is Neutralization?

Neutralization is a process of eliminating hazardous and toxic substances of Ethylene Oxide gas given to the atmosphere after sterilization phase.

There are three types of Neutralization technique can be implemented for ETO sterilization.

- - Water Scrubber,

- - Acidic Scrubber

- - Catalytic Oxidizer

What is Acidic Scrubber?

Acidic Scrubber is an additional device dissolving (Neutralizing) procedure of ETO Gas after sterilization phase. It utilizes Sulfuric Acid (H2SO4) and Sodium Hydroxide (NaOH) to eliminate Ethylene Oxide Gas as %99,999.

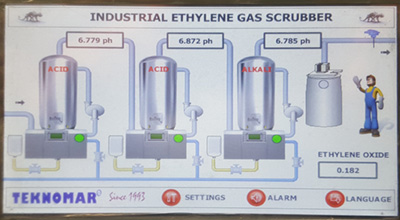

Acidic Scrubber contains three towers those are washing ETO gas in each of the nest with pressurized acidic water solution reducing the effectiveness of ETO gas. The third tower dilutes acidic solution with alkali and waste as Ethylene Glycol mixed with water.

Absorption of ETO gas needs to be dwelled longer than water scrubber. Analyzing of conversion speed and counted dwelling duration are the key parameters of the scrubber

Working Principle

First tower receives the ETO gas; constant washing inside the tower generates tornedo effect for homogenous washing. Most of the dilution is done in first phase. The second tower receives the ETO gas left from first tower and dissolving %99.999 percent, 0-1 PPM. The third last tower dilutes the acidic solution with Sodium Hydroxide and external tank stores the Alkali based salt and diluted ethylene glycol solution.

Why Teknomar Design Acidic Scrubber?

Acidic scrubbers are occupying an extra area in factory. This causes extra place arrangements for customers.

Teknomar Design Water and Acidic Scrubbers can be indoor and outdoor basis. The scrubbers are designed and built-in depending on the volume of sterilizers. There can be more than one sterilizer integrated into one acidic scrubber, too for cost effectiveness and multiple chamber selections.

Each of the scrubber towers are made of 316L food grade stainless steel and equipped with high-qualified sensor groups to detect PH, Solution water Level and Temperature.

Scrubber is integrated with SCADA software and controlled by SIEMENS PLC unit. ETO Detector is allocated at the exhaust for observing the residue left from exhaust.

System is preferred for GMP, CE, FDA registered factories.